The last time I worked on the F250 I was trying to deal with the sloppy steering. The first step was to bleed the power steering fluid. The plan was to jack up the front of the truck, so that the wheels were no longer in contact with the driveway, and then turn the steering wheel from lock to lock a number of times with the engine running.

Before carrying out this plan I decided it would be smart to move the F250 onto the most level part of the driveway. Unfortunately, while moving the truck, I discovered it was losing a lot of oil.....out of the tail pipe! Yes, you read that right, the exhaust fumes were more oil than fumes, and I had a nasty slick across my driveway to prove it.

There are two primary causes for oil blowing out of the tail pipe: It could be that oil is getting past worn piston rings, or it could be because the valve seats are worn. Or both. Either way, it's an unplanned engine rebuild and I already have one of those to deal with.

I spent a few minutes spreading cat litter over the stray oil, and then I went inside to cry into my cup ot' tea. And that is where fate intervened, because at that exact moment, I received a text from my friend Ninja asking if I knew anyone that wanted to buy a running V8 289 that had previously been in a '66 Mustang.

Fast forward a couple of weeks and we spent a few hours on a very pleasant December afternoon loading the "289" into Ninja's '63 Ranchero and transporting it to the Sheep homestead.

|

| We used the hoist to lift the engine on the stand. |

|

| And then we made sure it secure. |

|

| On the road... |

|

| In the garage after unloading. |

|

| I also took possession of the hoist. |

Once I had the "new" engine in the garage I had a look at the casting number on the block and found D4DE-6015-AA. The "6015" is Ford's code for an engine block, so can be ignored since it is present on every block. The rest of the code breaks down to a 1974 V8 small block with 302 cubic inch displacement and 2-bolt main caps. So, it may well have come out of a '66 Mustang, but it was clearly not original to that vehicle.

The next step was to do the same with the engine in the truck - it was supposed to be the original '67 V8 with 352 ci, making it a big block engine, and therefore not compatible with a 302 (or a 289 for that matter). But I had my doubts that it actually was....the intake manifold had the date code 1973 for one thing, and the chrome valve covers have a small block bolt pattern. To access the casting number on the block the starter must be removed, so I did that first, and then a close look under the block at the passenger side revealed: D4DE-6015-AA. And that's not a typo, it really is the same block from the same year. Perfect! This turn of events goes to prove that if you work hard enough at something for long enough you will eventually have some luck.

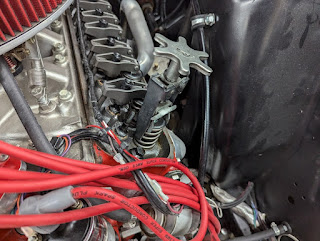

I pulled the original inline six engine out of the Mustang - with help - and I installed the V8 that is presently in that car with a whole team of helpers....but this time I'll be doing it mostly by myself and I'll be project manager for all of it. And I'm excited! Below is the last photo of the engine bay before I tore into it a few days before Christmas:

I still need to disconnect the engine from the transmission and from the mounts before it can be pulled out. Stay tuned for further developments!