To recap, the '68 has been off the road for about five (5) months while I have been trying to figure out why the engine was making such an awful noise, when running that is...

I discovered from my leak down test that cylinder #5 was leaking air through the exhaust valve. Or to put that another way, the exhaust valve was not closing when it should do. The next step is to find out why. I used a valve spring pressure tester to compare the spring at the #5 exhaust port with the other springs and it was much weaker. Conclusion: damaged or broken valve spring.

I didn't have a clue what spring to buy, but luckily I do have the original invoice from Summit Racing from when I bought all the engine parts back in 2014.....so I dug that out and ordered a replacement spring. Which was out of stock....grrr...

While I was waiting I acquired a valve spring compressor from the same BAMA buddy that lent me the leak down test kit and the tool for assessing the spring pressure. I live by the rule: if you need it once, borrow it; if you need it twice, buy it. I'm lucky to have friends that have a lot more specialist automotive tools than I do and are willing to let me borrow them occasionally.

|

| valve spring compressor |

|

| valve spring being compressed |

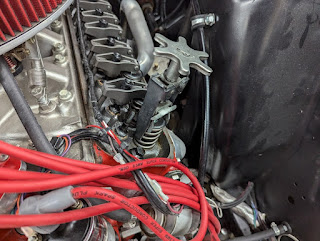

After installing the new spring I adjusted all the valves, put the covers back on and installed some new spark plugs. Then I discovered that one of my plug wires has been destroyed by heat from the headers:

While I was waiting for the replacement plug wires to arrive, I decided it would be a good time to change out my export brace. The new-to-me version is made of much thicker metal, which is difficult to discern from photos. It should stiffen the engine compartment and improve handling. I also plan to have subframe connectors installed, which should give a massive handling improvement, but I need to get the car running again first.

This time around I replaced them with chromed-plated caps that I bought from NPD. This looks much better and was well worth the extra $$$:

After that, I tried to fire up the car and....no dice! The starter was spinning, I was getting spark, and there was fuel in the float bowl...so it must be compression. My first thought was that the valve adjustment was off, so I had a friend who knows what he's doing come by and have a butchers.

For this engine, which is a 1969 Ford 351 Windsor, the valve adjustment is three-quarters of a turn past the position where the push rod can still just be manually rotated when the cylinder is at Top Dead Center (TDC). It follows that the crankshaft must be appropriately rotated between each valve adjustment. While there was a tiny bit of play in one or two valves, they we pretty much spot on. Next we pulled the distributor and tried spinning the oil pump shaft with an electric drill. (Note: the drill must be in reverse). This is where it got concerning because instead of oil being pumped through the push rods there was....nothing! Oops...no oil pressure! This was confirmed at the instrument panel where there was no needle movement with the ignition on:

The simplest explanations for a complete lack of oil pressure include a bad oil pump, a blocked oil pickup or a pickup that is damaged such that it is easier to take in air instead of oil. So....I removed the crossmember, dropped the steering, pulled the mini starter and with all that out of the way I could drain the oil and drop the pan. Luckily it was the day after Thanksgiving and Terry Sheep was in town to lend a hand, pass me tools and wipe up spilled oil etc. We installed a new oil pump and pickup which I got from Summit - you can't beat their overnight shipping:

After that I refilled the sump with clean oil and.....still absolutely zero oil pressure. This indicates a serious blockage somewhere in the engine which is clearly bad news. The next step is to pull the oil filter and have a look inside. Before that we had to (again) drain the oil, and this time there were several sizable chunks of metal that flowed out with it:

The same metal fillings on a paper towel:

I pulled the oil filter and left it to drain out overnight:

The next day I used a tool I just bought to cut open the oil filter. To be honest, you could quite easily do the same thing with a regular can opener or even a cutting wheel if you were careful. But I never miss a chance to buy a new tool if I can help it!

This is the snail, out of its shell, so to speak:

A mixture of fine metal fillings and even a fleck of red paint were found inside most of the folds:

A sample of filings transferred to a paper towel:

No comments:

Post a Comment